REFERENCES

- Caputi S, Murmura G, Ricci L, Varvara G, Sinjari B. Immediate denture fabrication: a clinical report. Ann Stomatol (Roma). 2014 Feb 4;4(3-4):273-7.

800-854-7256 USA

Learn about some of the perks of immediate dentures from a digital lab.

Being able to provide your edentulous patients with quick and reliable temporary solutions epitomizes the impact dentistry has on the everyday lives of so many people. By providing patients with a functional, esthetic provisional, you are saving them from the embarrassment of missing teeth for an extended period, keeping their smile intact for the time in between their final restoration while also supporting the post-extraction healing process.

But with so many temporary options to choose from, what is the right choice? Although you should choose whatever temporization method you feel comfortable with, this post will go through the many advantages of a 3D-printed immediate denture. Prescribing an immediate denture should not be an anxiety-inducing process. With the advancement of digital technology in dentistry, it is easier than ever to produce high-quality, better-fitting solutions for patients in need.

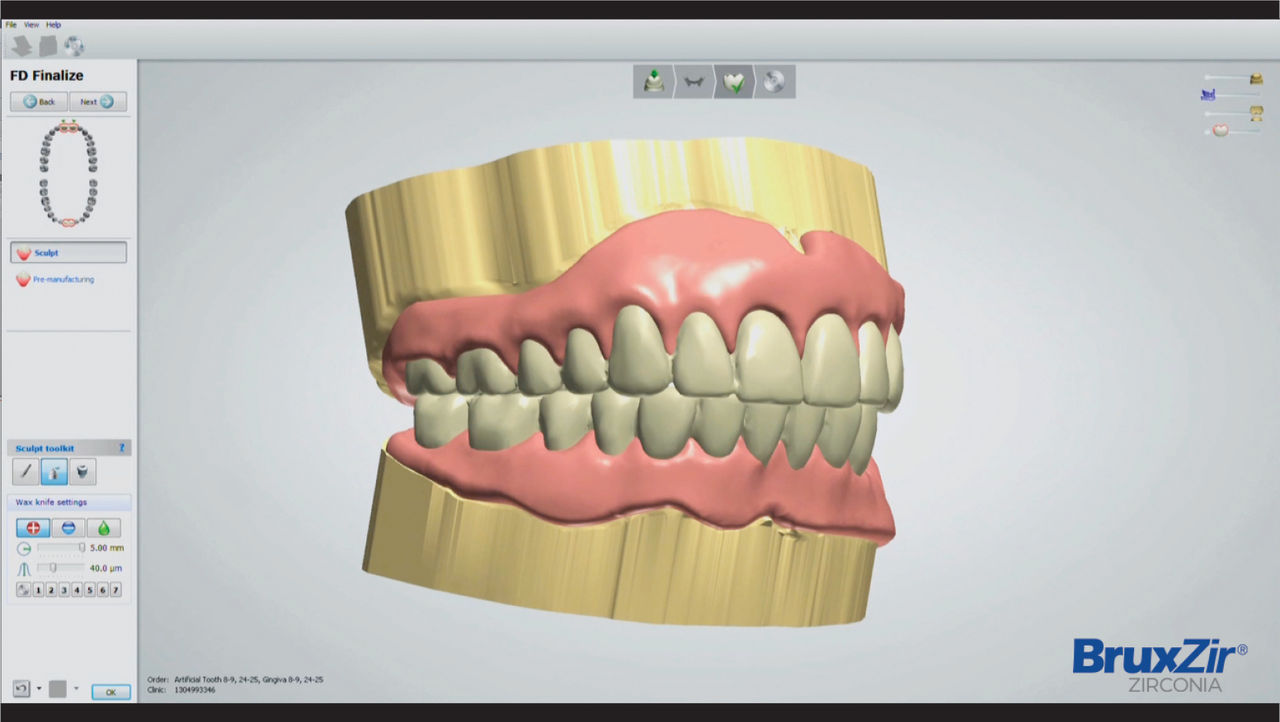

Immediate dentures are removable appliances made prior to the extraction appointment that are then immediately delivered post-extraction. They are primarily used as provisional prostheses during the healing process and are meant to be used until the patient is ready for definitive treatment. Traditionally, these immediate appliances do not have the same quality of fit, finish and function as a definitive denture. But with the application of 3D-printing and digital design software, they can look natural and lifelike, giving the patient confidence during their healing stage.

Since immediate dentures are meant for placement immediately following tooth extraction, they do not go through a complicated fitting process. During the first appointment, prior to tooth extraction, impressions are taken of the patient’s mouth. These can be taken via intraoral scanner or with the use of a physical impression. At the laboratory, the impressions are used to make a digital model of the patient’s mouth, where the teeth are digitally extracted and the appliance is designed in a post-extraction environment. Once the prosthesis is sent back to the clinician, the patient’s teeth can be removed.

Silicone-based reline material is a great choice when relining 3D-printed immediate dentures because it works best with the 3D-printed base material. Immediate dentures are placed right after tooth extraction, helping protect the healing ridges while improving esthetics.

The use of immediate dentures helps maintain the soft tissue contour of the face, preventing the cheeks from falling in and giving the sunken face appearance. This can be important for your patients who are already dealing with the trauma of losing their teeth, making a more normal appearance a meaningful factor for them.

Additionally, if your patient is using immediate dentures in anticipation of definitive complete dentures, the time spent with the provisional can act as a practice run for the final restoration. The practice of eating and speaking with the dentures will provide the patient with time to establish good oral habits and make the transition much easier.

Lastly, the biggest benefit of immediate dentures for your patients is not having to appear in public without any teeth. They can avoid any of the embarrassment or discomfort of edentulism since the provisional prosthesis allows them to retain a more natural, esthetic smile.

Immediate dentures are a great provisional option, but where does 3D printing come in? Adopting 3D-printed dentures into your workflow can make for a powerful tool that will produce substantial results without having to add any new equipment or software.

Simply Natural™ 3D-Printed Dentures from Glidewell are one example of a 3D-printed provisional. They are fabricated based on the patient’s pre-op scan and the technician’s design, ensuring an accurate fit and exceptional esthetics.

3D printing, also known as additive manufacturing, is a form of fabrication in which a digital file or image is created three-dimensionally. Layers and layers of materials are systematically cured on top of one another until the digital image is fully realized, making for an extremely accurate prosthesis directly from the file.

An example of a 3D-printed immediate prosthesis is the Simply Natural™ 3D-Printed Immediate Denture, which is fabricated by 3D-printing the denture base and teeth separately before bonding them together, ensuring an accurately fitting set of provisional teeth that’s right for the patient’s mouth. Requiring only a preliminary, pre-extraction impression prior to fabrication, they are an affordable, two-appointment solution for patients who want a quick provisional and for clinicians who want to ensure their patients’ extraction sites heal correctly.

Since all impressions are scanned and assimilated into a digital design software from the lab, the prostheses are subject to complete customization, accurately matching any requests or desires from the clinician. This gives the clinician the benefit of seeing what designs work and what could use adjustments before final delivery.

Prescribing 3D-printed appliances can be quick and easy. And although every lab has its own workflow, a large lab such as Glidewell has unique benefits for partnering clinicians. Glidewell’s proprietary workflow, Glidewell Intelligent Manufacturing (IM), allows any dentist to participate in digital dentistry without needing to invest in new technology or change their established habits. First, the advantages of 3D-printed appliances are available to any type of impressions—submitted either digitally via an intraoral scanner or traditionally through a physical impression technique—including those digitized by the lab from a physical impression.

The digitally designed dentures are fabricated using a 3D printer.

Because Glidewell has such an extensive infrastructure and uses algorithms supported by artificial intelligence (AI), clinicians can rest assured that the prosthesis they receive has gone through an extensive design process to ensure a good fit and natural esthetics.

As an added benefit, every case submitted to Glidewell is digitally archived—including those submitted by a physical impression. The benefit of this is that the prosthesis design is stored in a virtual cloud, making access to the restoration quick and easy. Should patients damage or lose their denture, a replacement can be printed from the virtual design without the clinician needing to submit additional impressions.

3D-printed immediate dentures are a comfortable, esthetic appliance that can provide the clinician and patient with plenty to be happy about. They combine the post-extraction healing benefits of immediate dentures with the accuracy and digital benefits of a 3D printed appliance. They save time by being available for placement after only two appointments and they are easily prescribed with just one pre-extraction impression. They are affordable and can be duplicated without the need to submit additional impressions. Lastly, and maybe most importantly, they provide the patient with confidence and normalcy while waiting for their final restoration, so they don’t have to miss out on any smiles in the meantime.

REFERENCES

Related Dental Articles

Dental Blog

Send blog-related questions and suggestions to hello@glidewell.com.