In the early summer of 2009, Glidewell introduced the dental community to BruxZir® Zirconia, a monolithic zirconia restorative material indicated as a tooth-colored alternative to PFMs and cast gold restorations. After nearly a decade of scientific evaluation by TRAC Research (the clinical studies division of the independent Gordon J. Christensen Clinicians Report®), BruxZir restorations still exhibited a 100 percent survival rate and zero terminal fractures.* And as of the tenth anniversary of its release, BruxZir had become the single most-prescribed brand of solid zirconia restorations, with almost 20 million BruxZir restorations prescribed and seated globally so far.

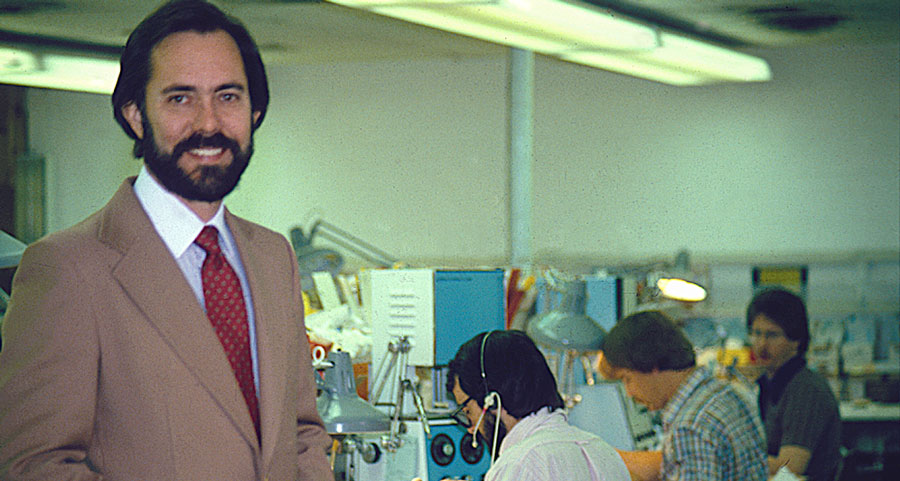

More recently, Glidewell’s drive for innovation was revealed with the introduction of the glidewell.io™ In-Office Solution—a restoration ecosystem that empowers doctors to produce high-quality BruxZir restorations chairside in under 45 minutes. “While it may seem counterintuitive for a lab-driven enterprise to assist its customers in producing their own restorations, we view it as an example of our ongoing commitment to provide dentists the tools and techniques needed to deliver treatment to more of those in need,” said President and CEO Jim Glidewell, CDT.